The journey for cruise passengers starts when they see and walk on to the vessel

The MSC Meraviglia is the first of a new fleet of high-tech ships MSC Cruises is launching over the next decade. Frances Marcellin went on board to speak to the team behind the ship’s cutting-edge technology

Cruise lines know that creating a good first impression is crucial for both their reputation, and the passenger’s experience. Providing a clean and safe passage for ships calling at ports plays an important role in the maintenance of a vessel.

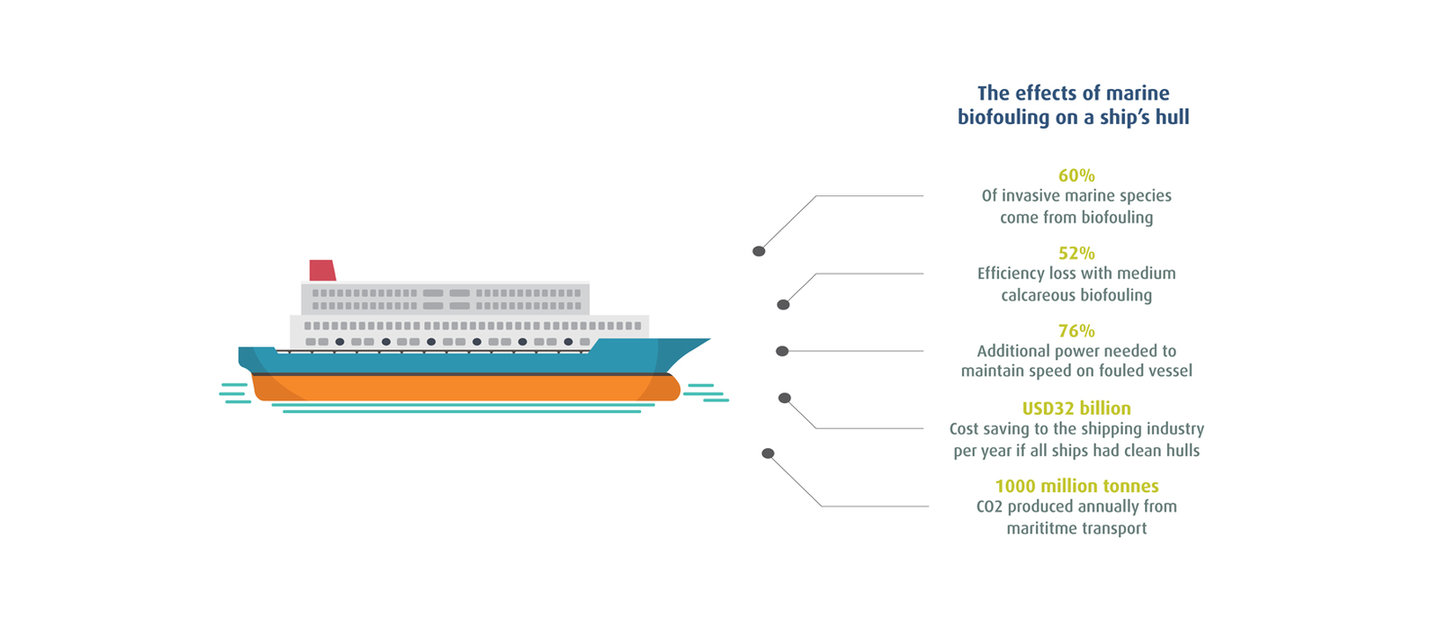

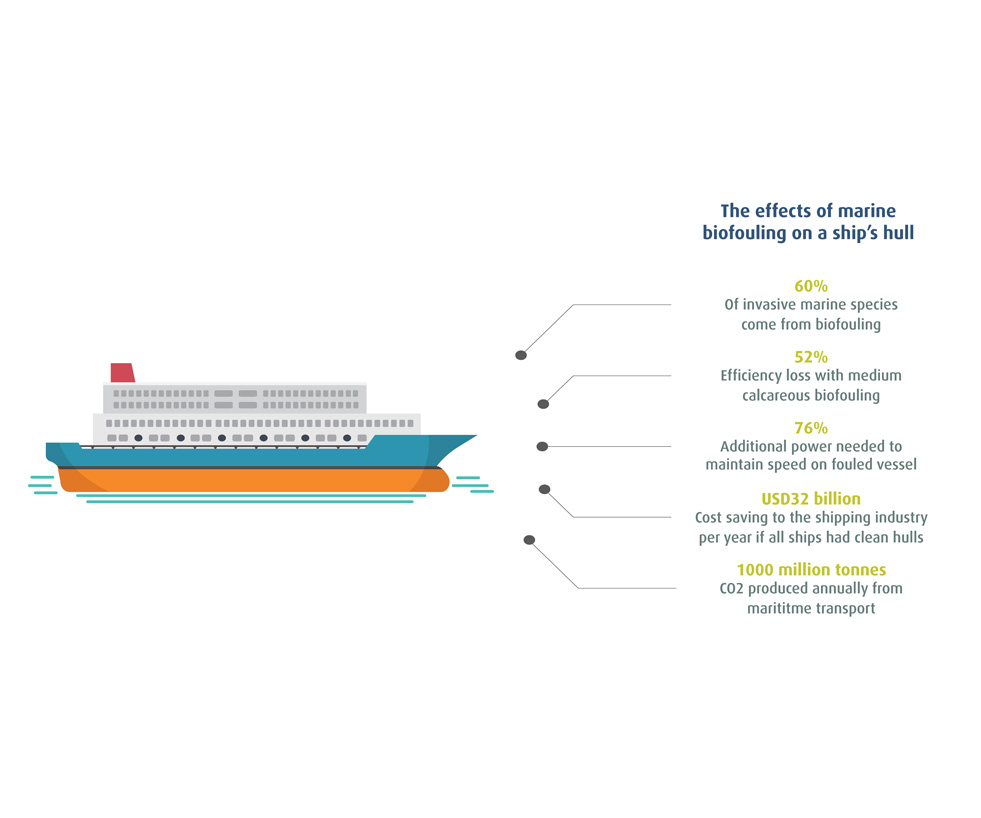

Rules governing the requirements for a vessel to enter a country’s waters are more stringent. At the same time, the need for regulations to combat the harsh effects of invasive aquatic species transported by hulls is becoming a top priority. Countries like the United States, Australia and New Zealand have already introduced tougher management plans to counter the effects of marine fouling into the sensitive ecosystem. Some of these guidelines include biofouling maintenance records and thresholds that could prevent cruise vessels from calling at their planned ports of call and reduce their itinerary, with all the implications that brings for passengers.

“All cruise vessels host hull fouling, whether a slight build-up of slime or the accumulation of microorganisms. Transferring invasive species across our oceans is an industry issue, regardless of sector,” says Simon Doran, HullWiper’s Managing Director. “Vessels need to be aligned with the new standards not only to safeguard their passage, but also to preserve the health of our oceans and reduce the harmful effects of CO2 emissions.”

Flame Retardant Carpet Protection Film protects carpets on floors, steps and stairs and is certified to the Marine Equipment Directive (Wheelmark).

HullWiper’s Remotely Operated Vehicle (ROV) is a ‘green’ solution that meets all local and regional environmental legislation.

The eco-friendly ROV gently removes fouling from vessel hulls quickly, efficiently and safely, leaving anti-fouling surfaces intact and undamaged. The secret lies in the way in which fouling is removed. Unlike traditional hull cleaning methods using divers with brushes or harsh abrasives, HullWiper uses high pressure seawater jets. All removed fouling is collected in a special waste unit and disposed of on land in an environmentally-friendly manner instead of being discharged back into the sea.

“HullWiper provides cruise lines with a cleaning solution that enables them to meet their responsibilities to protect the marine environment, without disrupting their business.” adds Mr Doran. “All our operations are compliant with IMCA and IMO guidelines.”

Data from biological analyses of the ROV’s post-filtration water reveals that the on-board filters are highly effective in filtering out the bio-fouling material removed from vessels’ hulls during cleaning. The concentrations of algae discharged are extremely low and likely in line with the natural rate of deposition from the bio-fouling growth on ships’ hulls prior to cleaning while berthed in port. Chemical testing results also show that the chemical levels in water discharged from the filtration units are well below the required concentration for all parameters.

Having a clean hull brings significantly reduced costs, thanks to reduced fuel consumption as a result of a more streamlined hull and better long-term operating efficiency. Studies show that a clean hull can improve vessel speed and savings of up to 40% on fuel consumption per voyage.

HullWiper is designed to clean 2,000m2 per hour in most weather conditions, eliminating the need for expensive down-time and extended port calls. As no divers are involved, cleaning can be done around-the-clock in port, day or night, saving time and eliminating the risk to human life.

“Cruise vessels work to a tight schedule. That’s why it’s important to plan voyages with measures to avoid unnecessary delays because of a fouled hull,” underlines Laurance Langdon, HullWiper’s General Manager. “Prior to entering a port, regular hull inspections may be performed and if a vessel does not meet local requirements, port authorities can request the owners or operators to take measures, at their own cost, to clean the hull offshore according to local standards and requirements, before they can enter.”

Flame Retardant Carpet Protection Film protects carpets on floors, steps and stairs and is certified to the Marine Equipment Directive (Wheelmark).

HullWiper aims to work closely with suitable partners at key cruise locations as well as other key port locations worldwide, through its recently launched leasing programme. By adding the environmentally-friendly hull cleaning solution to their portfolio of services, those leasing partners will reap the benefits of having the tools at their disposal to comply with regulation and also offer 24/7, safe and cost effective hull cleaning and inspections.

“Preserving the delicate balance of our marine eco-system is the new standard for hull cleans, and demand is growing,” says Mr Langdon. “Our leasing system is flexible enough that it gives vessel architects and designers the option to build the ROV into their design plans for an on board solution. That way, it can be used for short periods when convenient to maintain hull coatings and keep them foul-free, which is ideal for cruise operators who have short stays in ports.”

Thanks to HullWiper’s special waste unit, it has been cleared to operate inside the waters of ports in Sweden, Norway, Denmark, Singapore, Spain, Netherlands, Egypt, United Arab Emirates and elsewhere in the Middle East, with more to follow soon.

For more information on what HullWiper can do for you and your fleet, go to www.hullwiper.co